Rolex, the illustrious Swiss horologist, is synonymous with opulence, accuracy, and artistry. Through the years, Rolex has shrouded its production process in an air of intrigue, sparking the question: Is Rolex’s production process veiled in secrecy? In this article, we’ll embark on a journey to uncover the layers of transparency and enigma surrounding replica Rolex’s craftsmanship, unveiling what’s disclosed to the public and what remains enshrouded in mystery.

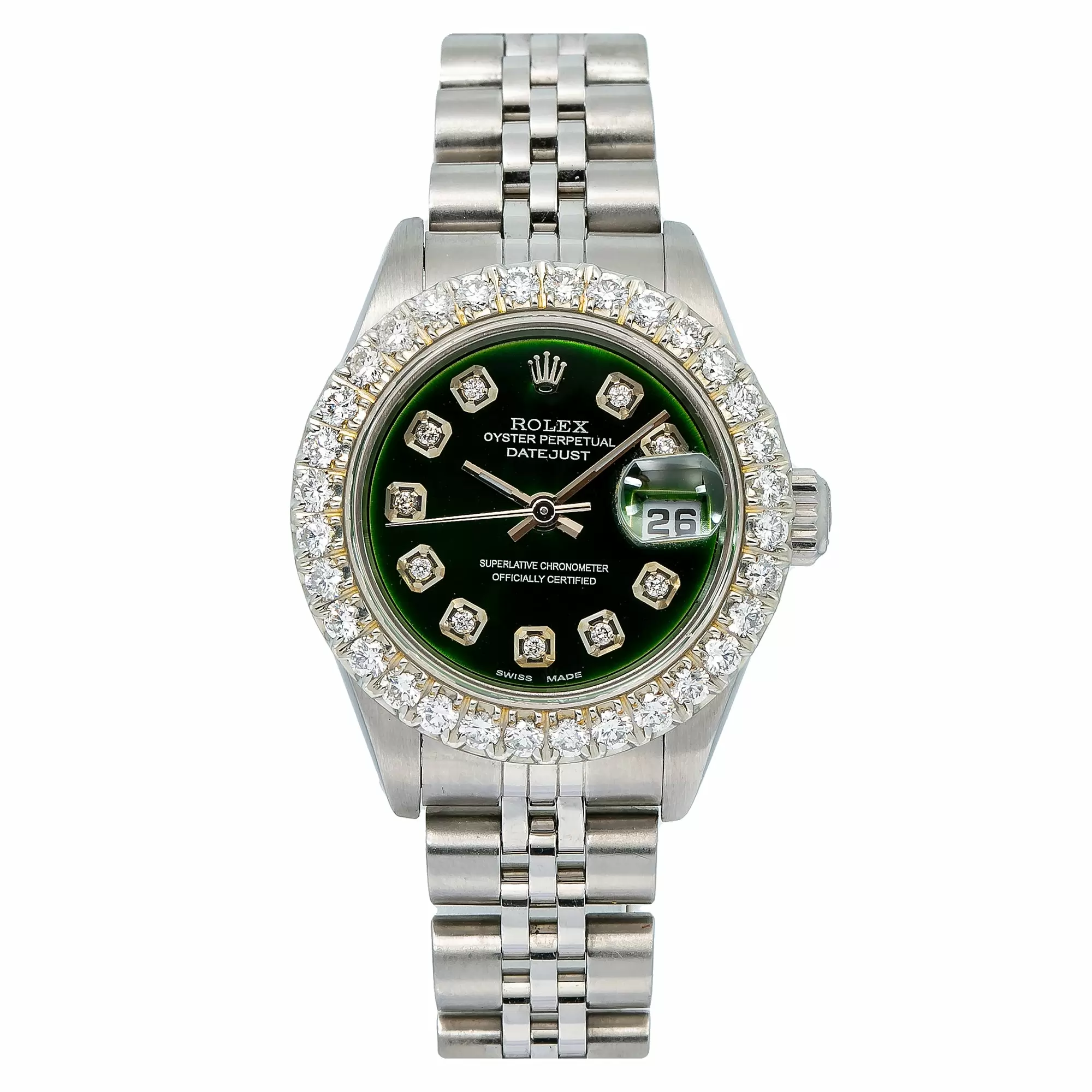

Rolex’s eminence rests on iconic designs like the Submariner, Daytona, and Datejust. These watch models are meticulously documented and readily available for public scrutiny. Rolex’s unwavering dedication to preserving the timeless elegance of these creations is palpable in their enduring charm.

Rolex’s hallmark is the use of premium materials like 18k gold, stainless steel, and exclusive alloys. While the precise origins of these materials may remain undisclosed, Rolex’s reputation for sourcing the finest elements is globally recognized.

Rolex is renowned for its in-house movement production. The brand conceives, crafts, and assembles its movements, ensuring the utmost precision and reliability. This facet of Rolex’s manufacturing is extensively documented and celebrated.

Within Rolex’s confines lies its very foundry, where the alchemy of gold alloys unfolds. The exact recipes and methodologies employed in creating these unique alloys are closely guarded mysteries. While Rolex divulges the purity of its gold, the intricacies of alloy compositions remain confidential.

While copy Rolex openly acknowledges the in-house production of movements, the intricate intricacies and proprietary technologies adorning these movements are concealed from the public eye. Precision engineering remains an undisclosed realm.

In essence, whether Rolex’s production process is entirely clandestine or not, the brand’s unwavering commitment to excellence remains unequivocal. This dedication is what resonates most profoundly with horological enthusiasts worldwide.